SASKATOON — A local tire recycling business has laid off another set of workers due to market pressures and the decision by Tire Stewardship of Saskatchewan (TSS) to redirect tires outside the province.

Shercom Industries president Shane Olson said the company sent immediate notification of layoffs to the Ministry of Labour Relations and Workplace Safety on Oct. 23, informing the ministry that 79 employees would be laid off effective Dec. 2.

Olson said the decision was made some time ago in accordance with provincial labour law. The employees affected by the layoffs have been with the company for more than 10 years, with some having worked there for over two decades.

“The recent layoff decision was made months ago, long before the writ was dropped. The timing of the decision is governed by the required notice as determined by Saskatchewan labour laws,” Olson said in an email to SaskToday.

“Any perceived effect these layoffs have on any particular party would be a direct result of that party's actions ... Shercom has to adjust to market pressures and industry realities as a private-sector business.”

Shercom had previously laid off 40 full-time staff involved in tire collection and processing, citing business needs. The 79 employees affected by the current layoffs work solely in value-added manufacturing.

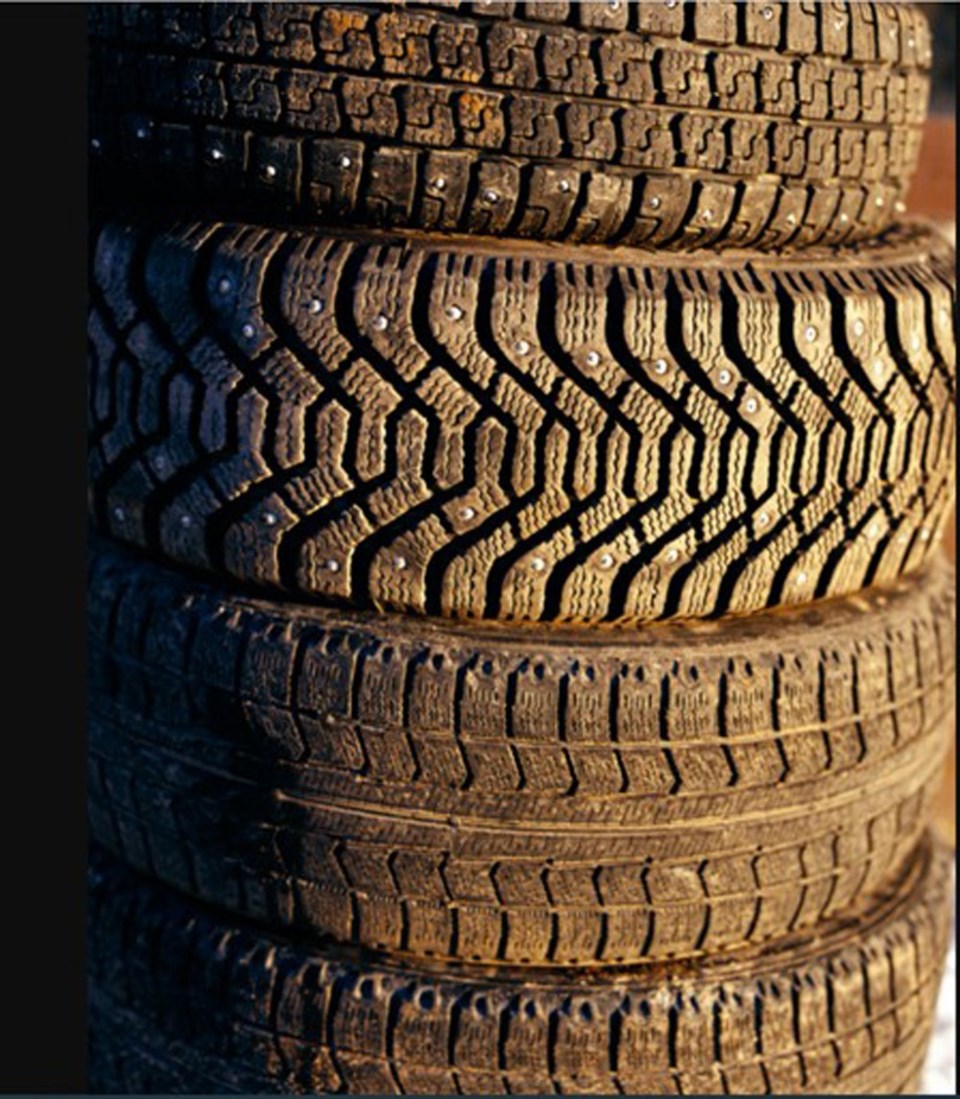

Since 1993, Shercom has been recycling used tires into products for commercial and residential projects, including garage and gym mats, rubber tiles, curb ramps, and speed bumps.

Olson said Shercom, a private business, had been recycling more than 50 million pounds of used tires annually until 2023, when the provincial recycling program was awarded to a U.S. company.

“Although our 30-year history has been marked with continual double-digit growth and job creation, the decision of the TSS, with the support of the Saskatchewan government, to redirect all tires to flow out of the province has been a singular factor that has interrupted the free market,” Olson said.

“The realities that Shercom is facing are far different from the messages being sent by the tire program and the government. Their promise? Lower carbon footprint, more jobs, higher value-added, cost savings to consumers.”

He added that Shercom has had to import 700 semi-loads of crumb rubber over the past 18 months from across Western Canada and Ontario, while Saskatchewan tires are being shipped out of the province.

“This has eliminated 120 jobs, not including other jobs Shercom would have created. These jobs didn’t move to Alberta or California. These jobs were eliminated. There hasn’t been a pound of crumb rubber made in Saskatchewan since the TSS directed the tires to the U.S. company. The cost of these losses will be measured in millions of dollars per year to the Saskatchewan economy, not to mention the growing liability of tire piles across the province,” Olson said.

“And although we no longer process used tires that way, we are still at the forefront of rubber recycling technology through innovative tools, technologies, and processes in the recycled rubber products we design. We are dedicated to finding new and better ways to reclaim, recycle, and reuse scrap tires as the base for innovative, eco-friendly products. Our efforts keep millions of pounds of material out of landfills, contributing to the well-being of our communities and the long-term health of our planet.”

Olson said Shercom has been in the tire recycling business for 30 years and pioneered a method to harvest rubber from hazardous tire waste, turning it into value-added moulded rubber products — a process no other private company in Saskatchewan had achieved.

“In essence, we took a hazardous material and turned it into a renewable resource that could be harvested for the benefit of the economy, the community, and the environment. With the failure of all other tire processors in this province, Shercom built a state-of-the-art $20-million processing plant in 2016 to handle all the tires in the province. This was done with the encouragement of the government,” Olson said.